Material Mastery: The Ultimate Guide to Velobike Sprocket Selection

Share

This Blog is a deep dive into the material engineering decisions behind Velobike innovations sprocket designs - specifically the materials we make them out of. From cost effective chromoly steel, the resilience of stainless steels and the weight of titanium alloys, This article will help you understand what makes each option stand out and how it influences your track cycling performance.

Ever wondered what goes into selecting the perfect sprocket for your bike? Well, buckle up, because we're about to embark on an exciting journey into the behind the scenes of the Velobike innovation design studio. Our guide today is none other than Ben France, an engineering intern with a knack for breaking down complex material science into bite-sized, easy-to-digest nuggets of insight.

The Contenders on the Track

At Velobike, the quest for the ultimate performance sprocket has led to the creation of four contenders, each machined from different metals and carrying unique qualities into battle:

-

Track Sprocket - The tough cookie, made from hardened 4130 Cr-Mo Steel.

-

Elite Track Sprocket - A refined version of the track sprocket, previously crafted from hardened 304 stainless, and now being replaced by 630 Stainless Steel. (The Enduo Track Sprocket(s) are also made from this material)

-

Elite Ti Sprocket - The weight weinee, made from Ti-6Al-4V Grade 5 Titanium, and sporting a tool-grade Titanium Nitride coating for extra durability.

- Elite SS Ti Sprocket - The Olympic contender, utalising a combination of the best qualities of all of the above! Constructed from 630 Stainless Steel, with a tool-grade Titanium Nitride coating ready for anything the track throws at it.

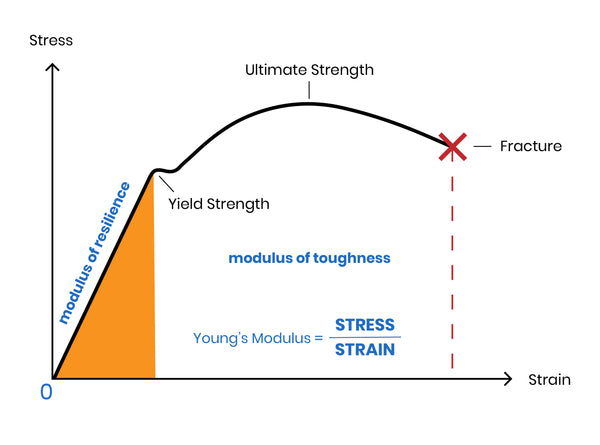

The Science Bit: Why Material Matters

Let's get down to specifics. Why do these materials matter? It's all about the interplay between stress, strain, and a little something called Young's Modulus. In layman's terms, we're looking at how much force these materials can take before they start to deform (that's the stress), how they squish or stretch under pressure (the strain), and their overall stiffness (cheers, Young's Modulus).

Breaking Down the Jargon

-

Stress and Strain: Imagine the pressure of a tight hug vs. a gentle squeeze; that's stress. Now, think about how much your body moves in response to the hug; that's strain.

-

Young's Modulus: This is essentially a measure of a material's stiffness. The higher the number, the less it deforms under stress. This metric is important when it comes to efficiency. The higher the Young’s Modulus is, the less it will deform under load from the chain - absorbing less energy while transferring more of it through to the wheel.

-

Yield Strength: The superhero's breaking point - how much force it can take before it starts to permanently bend or break.

-

Ultimate Tensile Strength: The ultimate showdown moment - the maximum stress the material can withstand before it calls it quits.

-

Hardness: Not just a personality trait, but a material's resistance to scratches and surface wear. Also deformation (to a degree).

- Fatigue Strength: Imagine doing squats all day. This is how long the material can handle being 'worked out' before it gets too tired (or breaks).

The Showdown: Comparing the Contenders

Each of Velobike's sprockets brings something special to the table. Here's a quick rundown:

-

The Track Sprocket is a good go-to for general use. Moderate durability and capable of handling high stress without a whimper. The Track Sprockets are a great affordable general purpose sprocket.

-

The Elite Track Sprocket steps it up with enhanced performance metrics, making it a reliable choice for riders putting out more watts such as track sprinters.

-

The Elite Ti Sprocket, with its titanium build and tool grade nitride coating, is all about top-notch performance with minimal wear and tear. Plus, it's about half the weight of the comparable Track and Elite Track sprockets - making your bike feel like it's filled with helium.

- Last but not least, the Elite SS Ti Sprocket stands out as the top level sprocket among the range. Intended for an Olympic spec track sprinting sprocket The highest quality stainless steel with top performance specs, offering a stellar mix of rigidity, toughness, and resistance to the extreme forces being transferred through it.

|

Material Property |

Titanium Alloy |

Titanium Nitride Coating |

Full Hard 304 Stainless |

4130 Cr-Mo Steel |

630 Stainless (Cond A) |

|

Young’s Modulus (GPa) |

113.8 |

- |

193 |

205 |

197 |

|

Shear Modulus (GPa) |

44 |

- |

77 |

80 |

77.4 |

|

Yield Strength (MPa) |

880 |

- |

965 |

435 |

1000 |

|

Yield Strain |

0.00779 |

- |

0.00500 |

0.00212 |

0.00507 |

|

Hardness |

41 |

85 |

41 |

17 |

38 |

|

Poisson’s Ratio |

0.34 |

- |

0.29 |

0.29 |

0.29 |

|

Density (kg/m3) |

4500 |

- |

8000 |

7850 |

7750 |

|

Yield Strength – Weight Ratio |

195.56 |

- |

120.625 |

55.414 |

129.03 |

Real Talk: What Does This Mean for You?

Choosing the right sprocket is more than just a matter of preference; it's about matching your cycling style and needs with the right engineered solution. Whether you're just about enjoying riding you bike, or all about the marginal gains, durability or aesthetics, there's a Velobike sprocket that's just right for you.

-

The Track Sprocket is a great affordable option for the casual rider, or often used as a training sprocket to keep the higher end ones reserved for race day.

-

If you're after something with a great balance of durability and efficiency, the Elite Track Sprocket might just be your new best friend, offering top-tier performance.

-

For the endurance riders out there seeking minimum weight while maintaining great performance characteristics, the Elite Ti Sprocket might be the best choice for you.

- And for those who demand nothing but the strongest, most durable and efficient sprocket in the industry , the Elite SS Ti Sprocket is ready to take you to the Olympic Podium.

In Conclusion: Your Ride, Your Choice

At the end of the day, the right sprocket is the one that meets your unique needs. Velobike's range of sprockets, with their diverse material choices and cutting-edge tooth design and precision engineering, ensures that no matter your riding style or level, there's a perfect match waiting for you. So, what's it going to be?

Written by Ben France and edited by Glenn Catchpole as part of an engineering internship at Velobike Innovation